From Blueprint to Build: How the Turnkey Steel Building Process Works

If you’re planning a construction project, you’ve likely heard the term “turnkey steel building.” But what does it actually mean? More importantly, how does it simplify your project from start to finish?

A turnkey steel building is about a seamless process where every stage — from the initial concept to handing over the keys — is managed by a single provider. This all-in-one approach eliminates the headaches of coordinating multiple contractors, juggling timelines, and managing unexpected costs.

In this article, we’ll walk you through the turnkey steel building process step by step, showing you how it transforms a complex construction project into a smooth, efficient experience.

Step 1: Initial Consultation and Needs Assessment

Every successful project starts with a conversation. During the initial consultation, you’ll sit down with your turnkey steel building provider to discuss your goals, budget, and timeline. Whether you need a sprawling industrial facility, a sleek commercial office space, or a specialised manufacturing plant, this stage is all about understanding your vision and identifying your unique requirements.

This stage is about building trust and establishing clear communication. By the end of this phase, you’ll have a well-defined project scope, a realistic timeline, and a shared understanding of what success looks like.

Step 2: Design and Engineering

With your goals mapped out, the next step is turning those ideas into a concrete (or, in this case, steel) plan. The design phase combines creativity with precision as architects and engineers collaborate to create blueprints tailored to your specific needs.

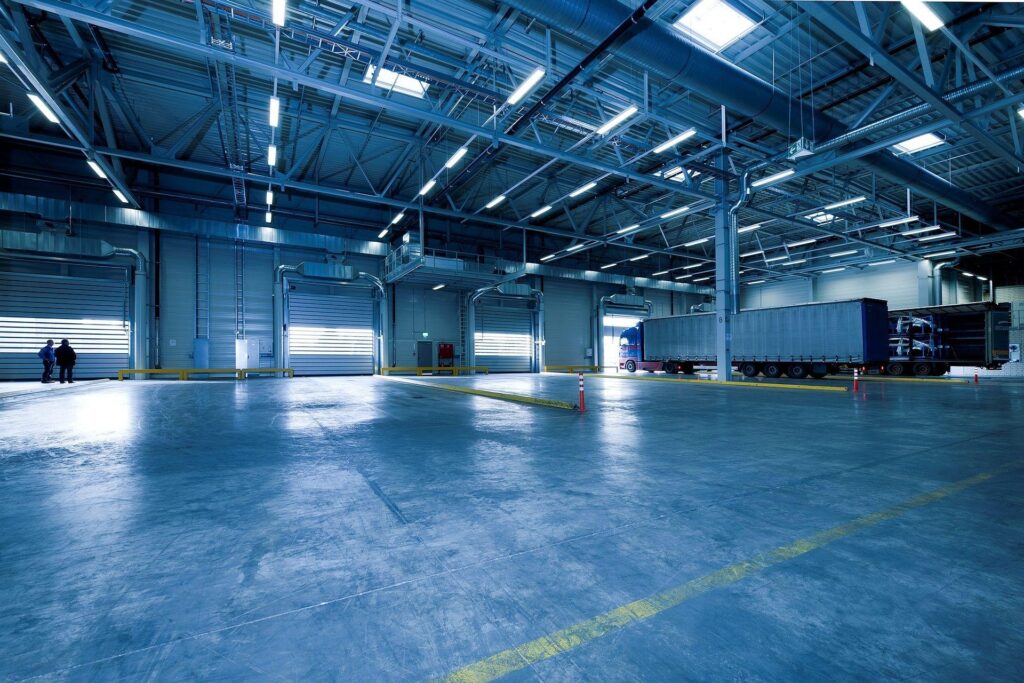

Customisation is a key advantage here. Steel buildings aren’t one-size-fits-all—they’re highly adaptable. Need an open warehouse floor plan with no interior support columns? Want energy-efficient windows or space for specialised equipment? These details are incorporated directly into the design.

Engineers then ensure every aspect of the building meets safety standards and local building regulations. They’ll calculate load-bearing capacities, evaluate wind and snow resistance, and optimise the structural design for efficiency.

By the end of this phase, you will have approved blueprints and engineering plans and be ready to move into the manufacturing stage.

Step 3: Fabrication of Steel Components

Unlike traditional construction, where materials are cut and prepared on-site, turnkey steel building components are prefabricated in a controlled factory environment. This step is where efficiency and precision take centre stage.

With the help of advanced machinery and cutting-edge technology, steel beams, panels, roofing materials, and support structures are precision-engineered to exact specifications. This controlled manufacturing process minimises human error, reduces material waste, and guarantees that every component fits seamlessly during assembly. In fact, prefabricated steel buildings typically use than conventional steel structures, making them both efficient and environmentally friendly.

This process also speeds up the overall timeline. While other construction projects might be waiting for materials to arrive or for on-site cutting to be completed, your steel components are already being prepared and quality-checked at the factory.

When the fabrication is complete, each part is labelled, packed, and delivered to the construction site, ready for assembly.

Step 4: Site Preparation and Foundation Work

While your steel components are being fabricated, the groundwork begins at the construction site. Site preparation is critical to ensure the steel building has a stable and reliable foundation.

This stage includes clearing and levelling the land, grading the soil, and laying utility connections if required. Once the site is ready, the foundation is poured according to the building’s specifications. Whether it’s a concrete slab or another type of foundation, precision is key to supporting the structural integrity of the building.

What’s unique about turnkey projects is that foundation work and component fabrication happen simultaneously. This overlap saves time and ensures the construction process begins without unnecessary delays once the steel components arrive on-site.

Step 5: Construction and Assembly

Once the site is prepared and the steel components are delivered, the real transformation begins. Your project starts to take shape during the construction and assembly phase.

Prefabricated steel components are assembled quickly, with bolted connections and pre-engineered parts fitting together seamlessly. Unlike traditional construction methods that can be bogged down by unpredictable weather or inconsistent materials, steel buildings offer efficiency and reliability.

A single project manager oversees the build, coordinating workers, materials, and schedules. This central point of contact ensures quick problem-solving, seamless communication, and fewer disruptions.

Because the structure is designed for efficient assembly, this phase often moves faster than clients expect, keeping your project timeline on track and your budget under control.

Step 6: Interior Finishing and Final Touches

With the steel structure in place, attention turns to the building’s interior. This stage is about transforming the steel shell into a fully functional space tailored to your needs.

Interior finishing includes installing insulation, electrical wiring, and plumbing. Additional features like partition walls, lighting fixtures, flooring, and ceiling treatments will also be added. The turnkey provider manages every element, ensuring all systems are installed correctly and every finish meets quality standards.

Step 7: Handover and Final Walkthrough

The final stage of the turnkey steel building process is also the most exciting: the handover. Before passing the keys over to you, the provider conducts a thorough inspection and walkthrough of the completed building.

This final walkthrough ensures that every detail aligns with your expectations and the original project specifications. Any minor adjustments or finishing touches are addressed promptly.

Once you’re satisfied, the keys are handed over, and the building officially becomes yours—ready for business operations, customers, or employees to move in and make it their own.

Why Turnkey Matters: Simplicity, Efficiency, and Peace of Mind

The turnkey approach is about delivering better results. Working with a single provider throughout the project eliminates the common pitfalls of managing multiple contractors, juggling conflicting schedules, and navigating budget overruns.

Every stage is streamlined, every detail is accounted for, and every challenge is managed by one team with a clear goal: delivering your building on time, on budget, and to your exact specifications.

Image Source: Pixabay